Acrylic Acid Application

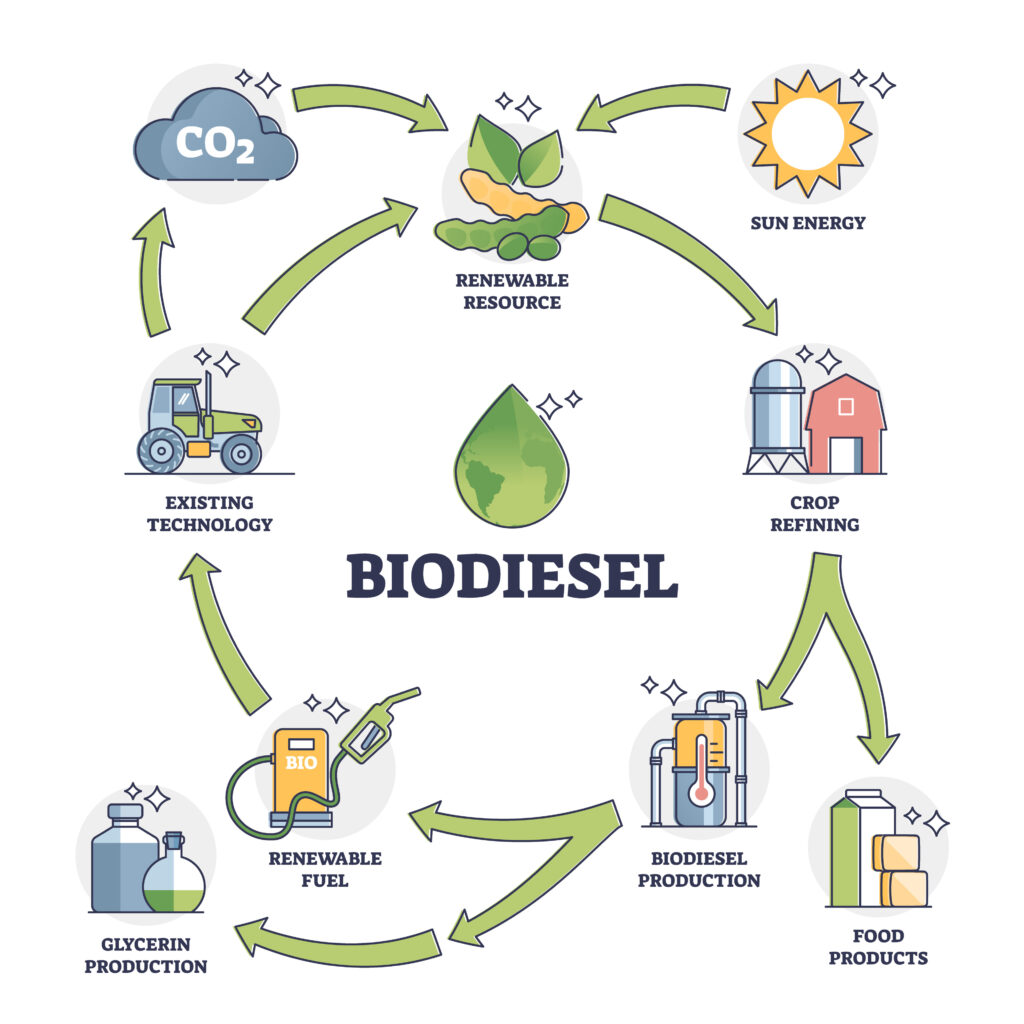

Renewable Biodiesel Byproduct Valorization

Acrylic acid market is $30B with growth driven by superabsorbent polymer (SAP) applications, as well as traditional acrylic paints, coatings, adhesives applications

Traditional process is two step gas-phase oxidation of propylene, a by-product of petroleum naphtha cracking to ethylene. Shale growth has shifted toward direct ethane cracking, limiting availability of propylene.

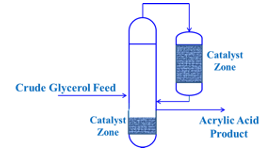

Emerging sustainable biodiesel processes converting vegetable oils, grease, cooking oils and animal fats produce glycerin by-product. KSE integrated catalytic and reactive distillation (iCARD) technology offers an intensified liquid-phase process to efficiently valorize this renewable waste stream to acrylic acid.

Join Us in Building a Sustainable Future

Discover how our technology can help your business reduce costs, enhance performance, and lower environmental impact.