Tetrahydrofuran Application

Valorization of waste hydrolysate stream for THF production

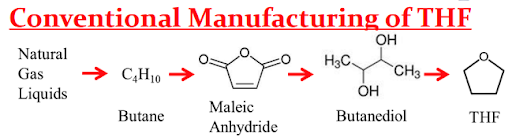

Traditional process for production of tetrahydrofuran (THF) is acid-catalyzed dehydration of butanediol sourced from fossil fuel natural gas liquids

Bio-based alternatives can be utilized to synthesize THF via a furfural route. For example, dissolving pulp processing requires the hemicellulose portion of wood chip raw material be removed prior to pulping. This pre-hydrolysate stream is typically discarded in waste-water system or burned in waste-boiler application. The 5-carbon waste stream is targeted for upgrade to furfural or THF production

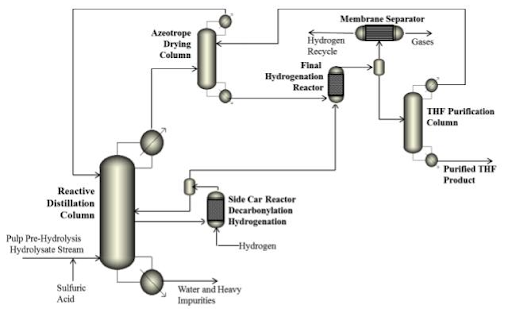

KSE technology utilizes hybrid reactive distillation with a side-car reactor to sequentially perform hydrolysis and dehydration of xylan-to-furfural, decarbonylation of furfural-to-furan, followed by downstream hydrogenation to high purity THF

Join Us in Building a Sustainable Future

Discover how our technology can help your business reduce costs, enhance performance, and lower environmental impact.