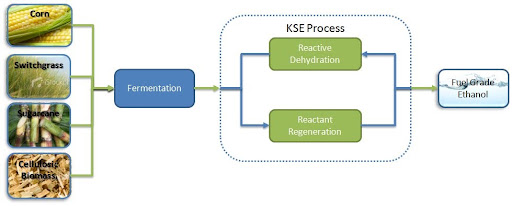

Bio-Ethanol Dehydration

Energy-efficient water removal in aqueous fermentation systems

Conventional ethanol plants utilize traditional distillation technology to dehydrate aqueous ethanol stream in a series of distillation columns, finished using pressure swing adsorption (PSA) to circumvent water/ethanol azeotrope at 95%. Fuel consumption increases exponentially as the azeotrope concentration is approached. Energy requirement for water/ethanol separation 6,750 Kg/kg ethanol is single largest contributor to operating cost

Utilization of KSE reactive distillation technology and catalyst system provides ~20% reduction in energy cost at 60% capital cost of traditional distillation/PSA configuration

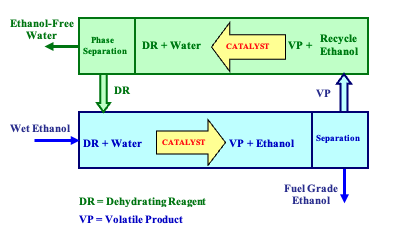

- utilizes a chemical cycle to replace the thermal distillation cycle

- Dehydration reagent (DR) added to wet ethanol

- DR reacts to form a volatile product (VP), readily separated from ethanol

- Dehydration reagent is readily regenerated and insoluble in water enabling facile phase separation

- Can run the cycle to remove ethanol or to remove water

Join Us in Building a Sustainable Future

Discover how our technology can help your business reduce costs, enhance performance, and lower environmental impact.