Technologies

Biomass Technologies

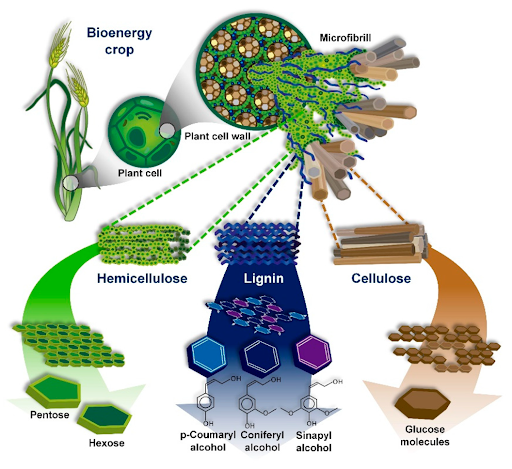

KSE process technologies are developed to reformulate and enhance various fractions of lignocellulose biomass. Targeted fractions include glucose-rich cellulose, pentose-rich hemicellulose, and aromatic-rich lignin. These biogenic sources of carbon provide renewable, sustainable components from which building block chemicals can be formulated to replace legacy single-use, carbon intensive petroleum products.

source: Hernández-Beltrán, J. U. et al. (2019)

Furandicarboxylic acid

KSE’s process for FDCA synthesis is based on uplift of pentose molecules found in hemicellulose waste streams,

transformed with biogenic + waste CO2, into building block chemicals which supplement or replace legacy petroleum analogs

In plastics, polyesters, and plasticizer applications.

Acrylic acid

KSE integrated and catalytic reactive distillation technology is utilized for efficient, liquid-phase conversion of glycerin by-product

Into acrylic acid, used in super absorbent polymer applications as well as paints, coatings, and adhevsives markets.

Ethanol Purification

KSE reactive distillation technology substitutes an efficient chemical cycle to replace the traditional, expensive thermal distillation cycle for dehydration during

Ethanol processing.

Tetrahydrofuran

KSE technology utilizing a hybrid reactive distillation configuration to sequentially perform decarboxylation of furfural-to-furan followed by

hydrogenation to high-purity THF demonstrates upgrade of hemicellulose waste streams as a substitute for legacy petroelum-based processing.

Join Us in Building a Sustainable Future

Discover how our technology can help your business reduce costs, enhance performance, and lower environmental impact.